Circuit Systems Company, Inc. is a family-owned business that has been operating in Arlington for over 40 years. Owner Grady King worked in the oil fields and consulted in several other industries where he saw an opportunity to manufacture a very small, specific part: aerospace bonding jumper cables.

“And so, he did what the American spirit tells you to do: he set up shop in his garage, and ended up building an empire,” said Leah Wilson, sales manager for Circuit Systems.

King enlisted his wife and a friend to help build the bonding jumper cables – he recalled that the two used to race to see who could build them the fastest. That friend still works at Circuit Systems to this day in the quality control department.

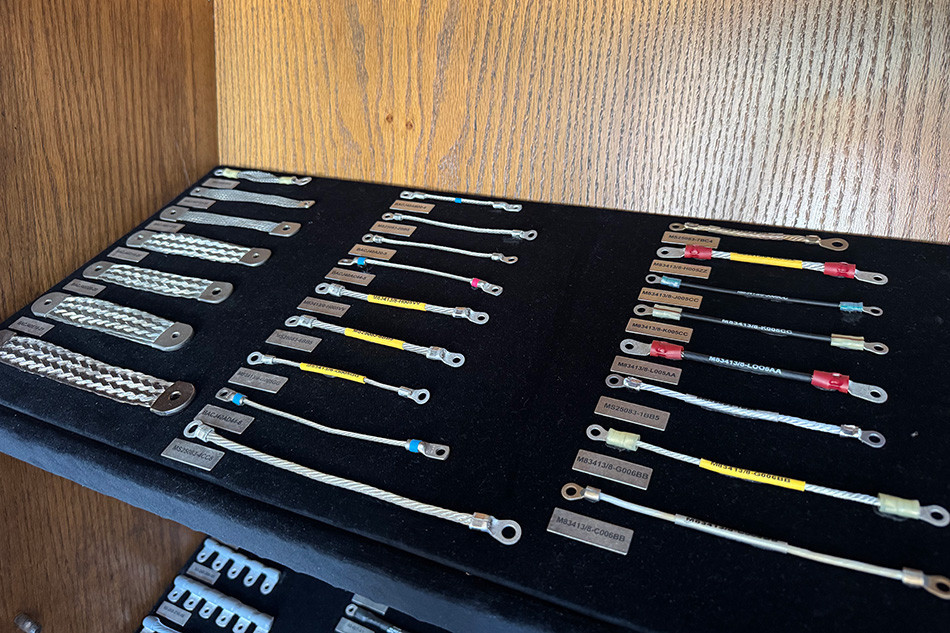

The parts themselves are simple — two metal terminals connected by a wire — although they’re made in a variety of sizes and metals, depending on the project need. However, they do a very important job: create a safe pathway for electrical current created by lightning on airplanes, helicopters and other aircraft. The result is that the aircraft doesn’t appreciably sustain the possible damaging effects of lightning strikes and maximizes passenger safety.

Circuit Systems is one of only three U.S. manufacturers qualified to make these parts for Boeing. They also work with Lockheed Martin, Bell, Airbus, GE and other major aerospace original equipment manufacturers, including NASA for use on the International Space Station and the Artimus program. They also employ five international distributors to cover all major airline markets for maintenance and reliability.

Their team of over 50 employees represents a diverse group, and they hire workers with attention to detail in mind — the parts undergo rigorous testing to maintain strict certifications including ISO-9001 and AS-9100. Wilson explained that they’re proud to largely employ several underserved population groups.

Business is booming for Circuit Systems. Wilson explained that the company has seen a 40% increase in sales year-over-year for the last three years, and they’re on pace to continue that trend. To accommodate the increase in production, the company will build an additional 20,000 sq. ft. facility on their land to complement their current 12,000 sq. ft. facility.

King cites Arlington’s central location as a primary reason for establishing, maintaining and expanding his business here (it doesn’t hurt that he’s a big Rangers fan and raised his family in Arlington).

The expansion will enable Circuit Systems to consolidate their equipment into one facility as well as scale up production. In addition to producing aerospace bonding jumper cables, bus bars and grounding straps, the company is now working to develop processes for plastic molded parts and other products related to electrical distribution.

King’s entrepreneurial spirit shines through in all his company’s products: clients ask him if he can manufacture something, and he figures out a way to do it.

Learn more about Circuit Systems Company, Inc. by visiting their website.